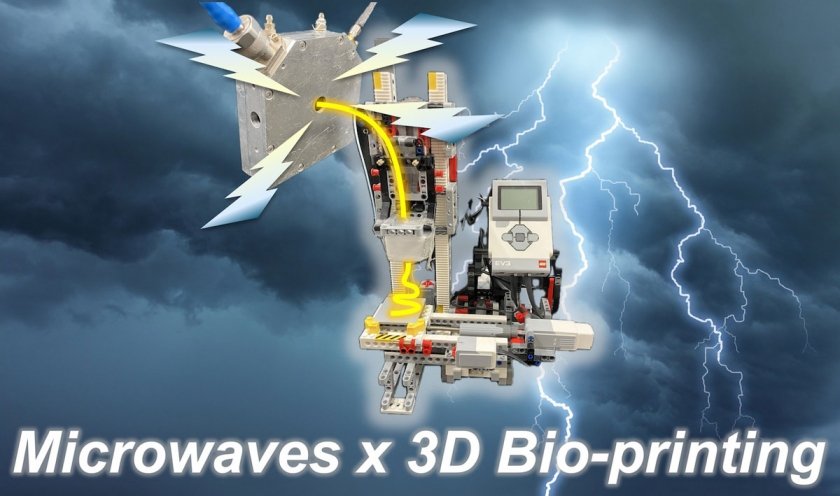

Associate Professor Tsubaki and his research team use Lego to print custom food for swallowing disorders

Researchers from Kyushu University have developed a new method to create customized food for individuals with dysphagia using a Lego 3D printer and microwave heating

Fukuoka, Japan--Researchers from Kyushu University and Cardiff University have developed a new method that uses a Lego 3D printer combined with microwave heating to print tailormade foods for people with dysphagia, a condition where swallowing is difficult. Publishing in Scientific Reports, the research team demonstrated that they could customize the texture, adhesiveness, and water retention of protein-based emulsion gels for dysphagia diets using controlled radiofrequency (RF) and microwave (MW) energy.

Dysphagia affects millions of people worldwide and can significantly deteriorate a person's quality of life. It is a particularly prevalent problem in rapidly aging societies like Japan. While texture-modified foods like purées can make swallowing safer, it is difficult to tailor these foods to the wide spectrum of dysphagia, as some individuals can tolerate more solid meals while others require much softer textures.

"For many people with dysphagia, meals are often limited to jelly-like materials, which can diminish the enjoyment of eating," explains Shuntaro Tsubaki, Associate Professor at Kyushu University's Faculty of Agriculture and first author of the study. "Our goal is to create food that is not only safe but also appealing."

Tsubaki saw an opportunity to apply his expertise in microwave engineering to solve this challenge. "Conventional heating methods heat everything inside indiscriminately--both the parts you want to react and the parts you don't," he elaborates. "Microwaves are different. They can be controlled to heat only specific materials selectively. This precision is the key."

The team first developed a bioink that is composed of two main compounds: a stable oil-in-water emulsion and an aqueous solution containing egg white protein and stabilizers. These are then combined with a small amount of magnesium chloride, which acts as a microwave absorption aid, helping the bioink to heat efficiently and promoting the protein denaturation necessary for the liquid to solidify into a gel. To print this bioink, the team constructed a custom 3D bioprinter using Lego Mindstorms EV3, inspired by previous research from their Cardiff University collaborators.

"After our initial tests proved we could control the gel's texture with different energy frequencies, we then loaded the bioink into the 3D printer and extruded it through a thin applicator," explains Dr. Tsubaki. "As the bioink passes through the applicator, we apply a controlled burst of RF or MW energy to it, turning the bioink into a gel. That gel is deposited onto the printing dish layer by layer."

The team's experiments demonstrated that by simply changing the frequency of the energy applied, they could produce gels with a range of properties suitable for different dysphagia diet requirements. When they used a lower frequency of 200 MHz, which falls in the radiofrequency range, the resulting gel was significantly harder and held its structure and water content more effectively. In contrast, using a higher frequency of 2.45 GHz, similar to that of a standard kitchen microwave, produced a gel that was much softer and more adhesive.

"The important thing is that we can control the texture though different frequencies, creating a customized texture for each person's needs," concludes Dr. Tsubaki. "Our new method holds potential beyond dysphagia diets--extending to artificial meat, functional nutrition, medical food, and even space rations. We are already working on other edible materials that can be 3D bioprinted. The ability to regulate protein aggregation and even trap flavors inside the oil phase could also lead to flavor-enhanced food-tech products."

(Written by Science Communicator Intern, Ken Eguchi)

###

For more information about this research, see "Radiofrequency and microwave 3D bioprinting of emulsion gel for dysphagia diets" Shuntaro Tsubaki, Ayane Ide, Daniel R. Slocombe, Oliver Castell, Ibrahim Maamoun, Noriyuki Igura, Scientific Reports, https://doi.org/10.1038/s41598-025-06804-1

For Research-related inquiries

Shuntaro Tsubaki, Associate Professor

Contact information can also be found in the full release

Contact

Contact

Access Map

Access Map